Philodendron Tissue Culture: Advanced Lab Techniques for 300% Growth Success

Struggling with contaminated Philodendron cultures and poor multiplication rates? What if a simple 5-stage protocol could transform your tissue culture success from 40% to 100% survival rates while producing 34 shoots per explant?

Mastering Professional Philodendron Micropropagation

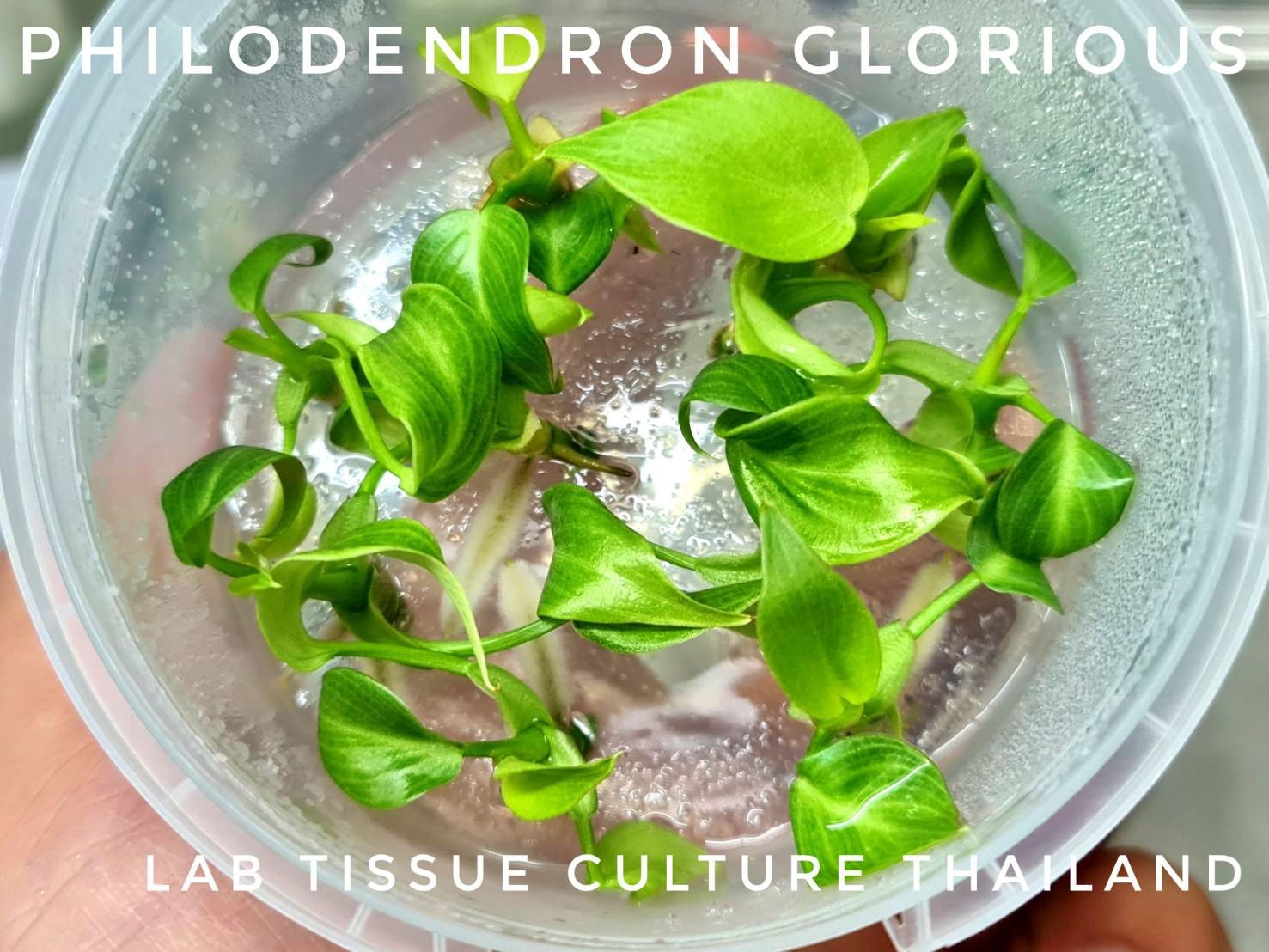

Philodendron tissue culture is one of the most important parts of ornamental plant propagation, and some variegated varieties are going for more than $500 per plant. But becoming successful means you have to master advanced laboratory techniques beyond simple protocols.

This invaluable manual breaks down the advanced techniques commercial labs have to reach a culture free from contamination, and multiplication speed of 34 shoots per explant.

Understanding Philodendron Biology for Tissue Culture Success

There are over 625 species of the genus Philodendron, which is part of the Araceae family, each possessing particular challenges for in vitro propagation. They are native to tropical Americas and have three specific growth styles that directly affect tissue culture methods – e.g. vining species of Philodendron i.e. Philodendron hederaceum; self-heading types including Philodendron ‘Pink Princess’ and tree-like ones such as Philodendron bipinnatifidum.

The secret ingredient to effective Philodendron tissue culture is the comprehension of its meristem activity patterns. Philodendrons, in contrast to the majority of ornamental plants, have apical and axillary meristems and regulate growth differently. Studies show that self-heading ones use higher concentrations of cytokinin (5.0 µM 2-isopentenyl adenine) than vining varieties (2.5 µM), and that tree-like varieties often need auxin supplementation in the establishment condition.

Advanced Laboratory Setup and Infrastructure Requirements

Essential Equipment Configuration for Professional Operations

Professionally produced Philodendron tissue culture lab uses specific environmental protection and special equipment. The setup starts with a Class 100 laminar flow hood which achieves 90 fpm ± 20% airflow and the final HEPA filtration process reached 99.97% efficiency at 0.3 microns.

To maintain this temperature profile, we have to control it to 23 ± 1°C with fluctuations less than ±0.5°C, something that is especially critical for the safety of the Philodendron cultures as heat stress can lead to vitrification.

It is well-known that lighting systems require particular attention, and white LED arrays offer 35-65 μmol m⁻² s⁻¹ photosynthetic photon flux density. According to existing research, Philodendron explants can thrive under 12-16 hour photoperiods based on the multiplication stage; variegated varieties require lower light intensities (25–35 μmol m⁻² s⁻¹) to retain color stability.

Water purification systems should be Type II reagent grade compliant with a conductivity ≤1.0 μmho/cm. Purity limits will prevent mineral pollution that inhibits organogenesis and is especially beneficial to use variegated Philodendron cultivars with increased sensitivity to water quality.

Strategic Laboratory Design and Workflow Optimization

The 4-zone laboratory layout maximizes efficiency at relatively low risk of contamination. Zone 1 involves media preparation and requires separate zones for chemical storage, pH manipulation and autoclave operations. Zone 2 is the sterile transfer area that requires positive pressure ventilation and UV sterilization cycles between sessions.

The environment zones have been set up in Zone 3 with customized growth chambers for Philodendron according to the requirements, whereas they have also included a growth room for observation and acclimatization.

Workflow optimization follows a one-way process, preventing cross-contamination. The clean equipment flows from washing-based to media prepared to sterile transfer zones, and is gowned with sterile gloves, face masks, and specialized footwear. All zones are separated by two doors, providing pressure differentials to minimize the movement of contaminants in the air.

Revolutionary Surface Sterilization Protocols

Silver Nanoparticle Enhancement for 100% Aseptic Success

In Philodendron cultures, conventional sodium hypochlorite sterilization yields only 25.9% aseptic explants. Nonetheless, introducing silver nanoparticles (Ag NPs) at 40 mg L⁻¹ for 60 min results in an increased success rate to 100% with 100% explant survival. This innovative protocol overcomes the main limitation that Philodendron tissue culture operators face.

It works by binding Ag NPs to the cell wall of microbes using its 100 nm particle size and being more useful (than disinfectant) as antimicrobials. The treatment protocol consists of the sequential immersion of Ag NP after cleaning with 0.15% polyvinylpyrrolidone solution, treatment with 70% ethanol for 30 s, 12 min of 1.0% sodium hypochlorite exposure, and Ag NP treatment optimized.

Strategic Explant Selection and Preparation

Philodendron varieties have markedly different optimal explant choice. For climbing types such as ‘White Knight’, 0.4 to 0.6 mm petiole segments yielded the highest adventitious shoot induction rates (52.6%). Self-heading species are better suited to small nodal parts with lateral buds and tree-like species require shoot tip explants for establishment.

Source plants pre-condition has a significant effect on sterilization success. Maintaining the donor plants under low humidity (60-70% RH) and moderate light intensity (150–200 μmol m⁻² s⁻¹) for up to 2 weeks prior to explant harvesting reduces endogenous contamination by approximately 60%. This physiological preconditioning increases explant vigor, while standard surface sterilisation should be performed to minimize the microbial burden, which is to be eliminated by conventional surface cleaning.

Optimized Media Formulation and Growth Regulator Strategies

Critical Basal Medium Modifications

As the base material, it is based on Murashige and Skoog (MS) medium, with the Philodendron specific treatments having a very positive effect in performance. Studies indicate that full strength MS salts generate more shoots per explant than half strength formulations which leads to 34 shoots per explant and 11.2 shoots per explant with lower salt.

And this response correlates with Philodendron native habitat requirements for mineral-heavy substrates. Sucrose optimization is not easy, but this trade-off works well; 30 g L⁻¹ is recommended for most Philodendron varieties. In addition, concentrations well above 40 g L⁻¹ inhibit the shoot multiplication via osmotic stress, and concentrations below 20 g L⁻¹ provide insufficient carbon for rapid growth on the osmotic medium.

Carbohydrate supplementation timing also affects results, with periods of solidification benefiting from slowly adding sucrose earlier in formation. Precise pH corrections: Philodendron cultures need 5.70-5.80 to be acidic prior to autoclaving. After autoclave time, pH typically falls by 0.2-0.3 units; it requires pre-sterilization adjustment for optimum growth conditions.

Stage-Specific Plant Growth Regulator Protocols

Further, in new protocols, a stage-specific set of plant growth regulators (rather than one-step approach) is utilized. The establishment step uses 8.0 µM benzyladenine, or BA to induce initial cell division and is followed by a multiplication media medium of 5.0 µM 2-isopentenyl adenine (2-IP) combined with 2.5 µM naphthaleneacetic acid (NAA).

This cytokinin-auxin interaction yields a higher efficacy relative to unlinked regulatory agents alone. The 2-IP/NAA combination produces 34 shoots per explant with 5.1 cm average length and BA alone produces 4.9 shoots (measured at 6.4 cm). It uses complementary signaling pathways that promote meristematic activity with correct length of shoots.

When regulators transition is key. Transfer of explants to multiplication media after 21 days optimizes shoot induction, whereas transferring beyond 28 days leads to decreased multiplication rates by 35%. The temporal sensitivity relates to the narrow window on maximum meristematic responsiveness for Philodendron tissues.

Multi-Barrier Contamination Control Systems

Seven-Layer Prevention Protocol

Seven-layer contamination prevention protocols are followed by advanced laboratories. The main barrier is the facility architecture, positive-pressure HEPA filtration to an ISO 5 cleanliness standard. 2.2 Staff education with competence testing, to ensure a proper aseptic technique is used throughout operators.

Chemical barriers are made up of wide-spectrum biocides such as PPM, at 0.5−1.0 mL L⁻¹. PPM is a continuous antimicrobial that has no phytotoxic effects on Philodendron cultures and especially affects endogenous bacterial contaminants not susceptible to surface sterilisation.

Physical barriers are sealed culture containers with separate venting system to avoid airborne contamination, yet allow gas exchange. In commercial operations, double-layer vessel systems – inner containers containing cultures within outer protective vessels – reduce contamination rates by up to 85%.

Early Detection and Molecular Response Systems

Utilizing systematic observation protocols helps to make sure early detection of contamination before symptoms are apparent. Microscopic examination performed daily at a 40x magnification also identifies bacteria 3 to 5 days before turbidity appeared. Through this earlier detection the contaminated vessels can be selectively removed before the dissemination to clean cultures.

16S rRNA gene sequencing based molecular detection techniques can pinpoint the specific bacterial contaminants to be targeted by the antimicrobial selection. This targeted approach decreases the broad-spectrum antibiotic usage which may stimulate resistance and at the same time keeps culture healthy.

Frequent environmental monitoring through settle plates and air sampling helps to trace the sources of contamination which helps to systematically enhance hygiene in the premises.

Commercial Production Scale-Up and Economic Optimization

Breaking Even: Production Thresholds and Efficiency Metrics

Profitable commercial Philodendron tissue culture operations will operate under certain economic thresholds. Break-even analysis also indicates minimum production of 10,000 plantlets monthly for facilities with a $50,000 initial investment. Labor efficiency becomes key, with experienced technicians dealing with 200–300 cultures per day – and ergonomic workstation designs and standardized protocols are therefore well-suited for this.

A cost estimate reveals media components make up 15–20% of total production costs and labor 45 to 55%. Profitability is significantly impacted by multiplication rates, with facilities with 34 shoots per explant operating at a profit margin 240% higher than facilities producing 10 shoots per explant. This multiplication benefit amplifies as the culture cycle continues.

It has great impact on the operation costs due to energy efficiency. LED lighting systems bring down electricity usage 60% over fluorescent options and offer better spectral quality for Philodendron growth. Programmable environmental controls provide optimal temperature and humidity monitoring, delivering 25-30% reduction in HVAC costs without compromise in culture quality.

Quality Control and Standardization Protocols

If strict, effective control measures of quality are in place, the quality of the product used is consistently high; a prerequisite for commercial success. Standard Operating Procedures (SOPs) should include record entry of protocol steps and regular training of staff in order to maintain competency.

Measuring quality: < 2% contamination, ≥25 shoots per explant, >95% acclimatization survival. The genomic stability validation by molecular markers affirms that tissue-based plants exhibit true-to-type properties.

Simple Sequence Repeat (SSR) marker characterization affords economical validation in the commercial industry, establishing that high-value variegated varieties preserve their unique traits through each subsequent culture cycle.

Systems of record-keeping need to track each culture from explant-to-final acclimatization from all angles to provide the necessary traceability for commercial customers. Digital inventory systems automate tracking and offer real-time production data, providing the need for operation optimization via electronic control.

Advanced Acclimatization Strategies for Maximum Survival

Environmental Transition Protocols

For successful acclimatization, environmental control is essential while the in vitro-to-ex vitro transition is critical. The protocol starts by decreasing culture room humidity from 95% to 70% over 7-10 days with temperature maintained at 23 ± 2°C, which provides a preconditioning before transplantation, which fortifies the tissues of the plant.

The survival rate is greatly dependent on the choice of substrate. Optimal performance is reported by the research with the use of 10% peat moss + 50% orchid stone + 40% coconut husk chips for this organism, the Philodendron ‘White Knight’ and the 100% survival rate. This duo can not only create good drainage but also retain moisture and function as a strong support structure.

Acclimatizing to new processes requires a careful balance of fertilization protocols. Starting with ¼-strength MS nutrients gives you salt resistance while bringing you the minerals you need to keep growing. This lets development of the root system occur while decreasing the pressure on soil in 4 to 6 weeks before switching to regular fertilizer programs.

Automated Environmental Control Systems

At a higher level of complexity, facilities utilize programmable environmental systems that automatically adapt by stages of plant development. Sensors measure temperature, humidity, light intensity and moisture, and adjust environments in real time to maximize growth and keep away stress-related losses.

Fog systems ensure uniform humidity management during the early adaptation and minimize transplant shock by offering stable microenvironments. While these systems run on 5-10 minute cycles the moisture levels can be excessive and may encourage fungal disease, while still maintaining some normal humidity for the stomatal function.

Whereas in vitro culture requires different spectral qualities than lighting systems for acclimatization, these lighting systems used for the acclimatization process require different spectral qualities. LEDs of full-spectrum LED arrays can provide 150-200 μmol m⁻² s⁻¹ to facilitate photosynthetic adaptation, and are resistant to the effects of photoinhibition which could occur with the high-power lighting during initial transition periods.

Troubleshooting Complex Culture Problems

Vitrification Mitigation and Correction Strategies

Vitrification is a remarkable difficulty in Philodendron tissue culture as transparent, water-sodden shoots do not develop properly under normal circumstances. This physiological condition is due to high humidity, wrong amounts of the cytokinin, or not enough gas exchange.

The prevention starts with preserving a sterile environment while preserving ventilation in the culture vessel. Correction work involves transferring the cultures to medium having lower, 2.5 µM instead of 5.0 µM 2-IP, 2.0 g L⁻¹ activated charcoal to remove the excess ethylene. The concentration of agar increases from 0.7% to 0.9%, giving the media more firmness, therefore lowering the water content, which facilitates vitrification.

Some cultivars, like Philodendron, are genetically more sensitive. Certain variegated varieties present this need and hence need modified protocols with reduced cytokinin concentrations and improved ventilation systems to reduce the risk of developing this disorder.

Browning and Oxidation Management

Excessive phenolic compound oxidation leads to premature browning in normal Philodendron tissues. Pre-treatment with antioxidant solutions (150 mg L⁻¹ ascorbic acid and 100 mg L⁻¹ citric acid; 30 min pre-surface sterilization) is a preventive measure.

Polyvinylpyrrolidone (PVP) media supplementation (0.5 g L⁻¹) can effectively bind phenolic compounds such that tissues will not show discoloration. This regular subculture every 14–21 days prevents the accumulation of oxidized compounds while keeping the nutrients sufficient for continued growth.

1.0 g L⁻¹ is another option for activated charcoal protection from oxidation as well as better media clarity for observation. Charcoal can adsorb plant growth regulators, resulting in the need for targeted targeting of cytokinin and auxin concentrations.

Emerging Technologies and Future Developments

Bioreactor Systems for Large-Scale Production

Temporary immersion bioreactor systems are the future of commercially operated Philodendron propagation systems that, with an automated culture condition control solution, can minimize labor needs by 70%. These systems alternate a cycle between immersion and aeration, obtaining the optimum nutrient uptake without causing hyperhydricity.

Using the present bioreactor setup, multiplication rates of 45-50 shoots per explant are achieved as compared to 34 shoots in agar-based systems. Higher efficiency is observed in higher gas exchange and better nutrient availability, which is critical for high-value variegated Philodendron varietals.

The scale-up concerns involve design enhancements in vessels, automatic media replacement mechanisms and integrated harvesting. Commercialized systems that handle ten thousand explants each month would demand advanced control systems for monitoring pH, dissolved oxygen and temperature at this level of growth.

Genetic Transformation Applications

Recent studies explore genetic transformation protocols for Philodendron improvement toward increased resistance to disease and favorable growth profile. Agrobacterium-based transformation protocols with selective Agrobacterium for the Araceae family can produce 12-15% efficiency.

CRISPR-Cas9 gene editing tools are designed to change traits such as increased variegation stability, rooting and acceleration of growth rates. These are powerful technologies for the very precise editing of plants without the intergenerational genetic integration, which also allays consumer fears such as genetically engineered plants.

Safe testing and regulations for modified Philodendron genotypes would be extensive. Nevertheless, these requirements could potentially be overcome by non-transgenic gene editing strategies that offer trait improvements desired for the genetic processes.

Key Sources:

Micropropagation of Philodendron ‘White Knight’ via Shoot Regeneration from Petiole Explants | PMC

Micropropagation of Lacy Tree Philodendron Using Shoot Tip Explants | ASHS HortScience

Plant Tissue Culture Essentials: Equipment Guide | Plant Cell Technology

Setting Up a Tissue Culture Lab | PhytoTech Labs

How to Build Your Own Tissue Culture Lab | Plant Cell Technology

Tissue Culture Contamination Prevention | Plant Cell Technology